Professional sheet metal components engineered for industrial applications with precision manufacturing and reliable performance worldwide

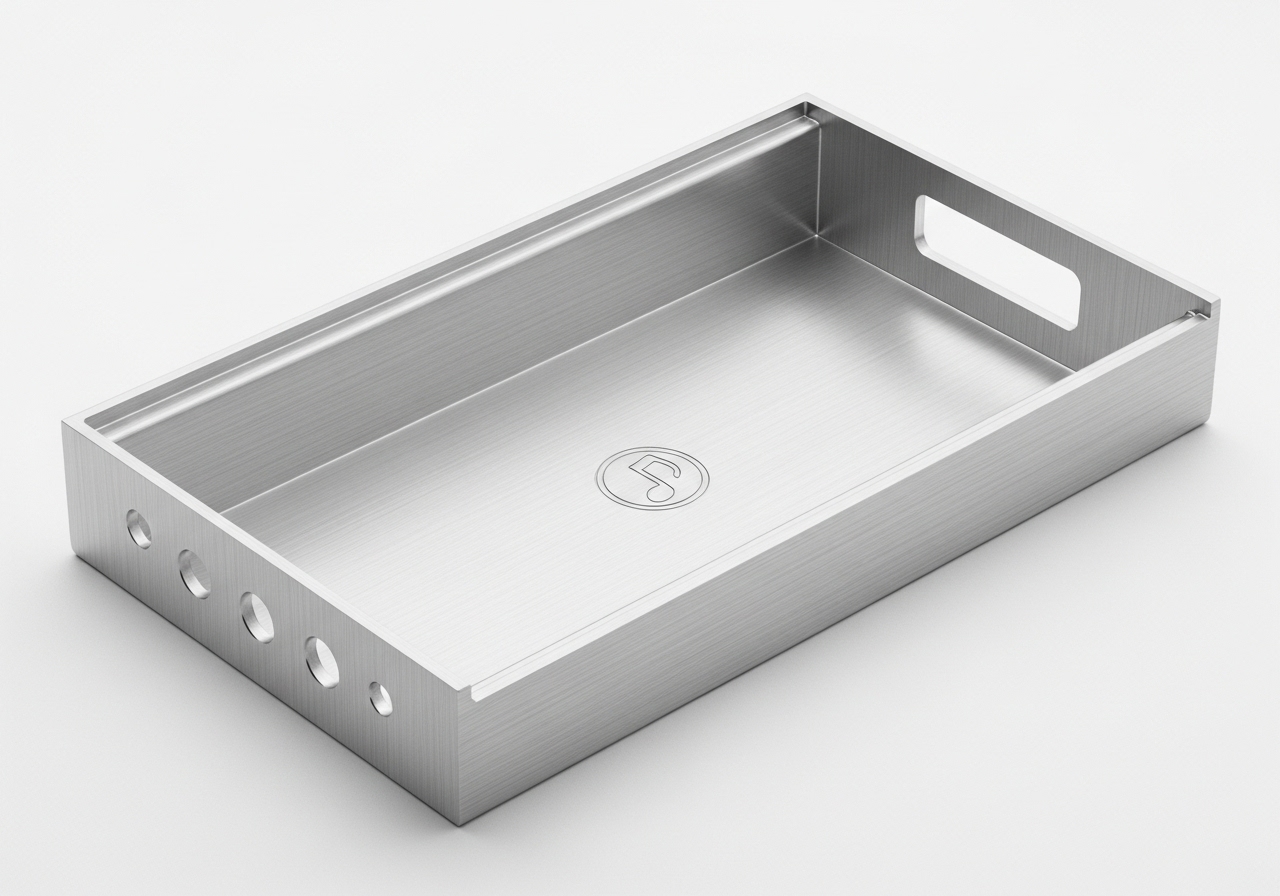

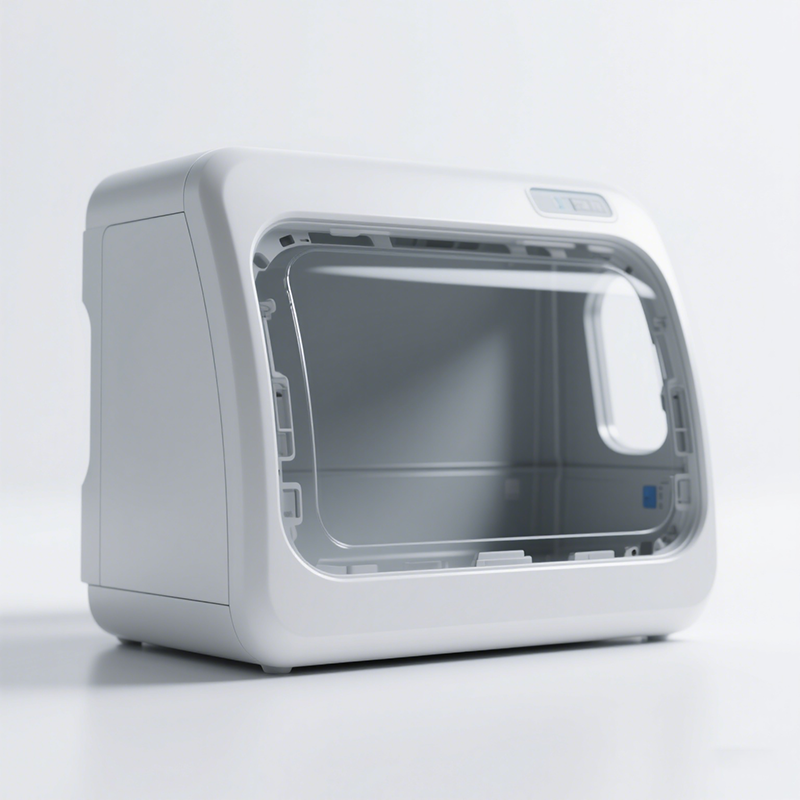

Custom metal enclosures providing superior protection for electronic equipment, control panels, and sensitive industrial components

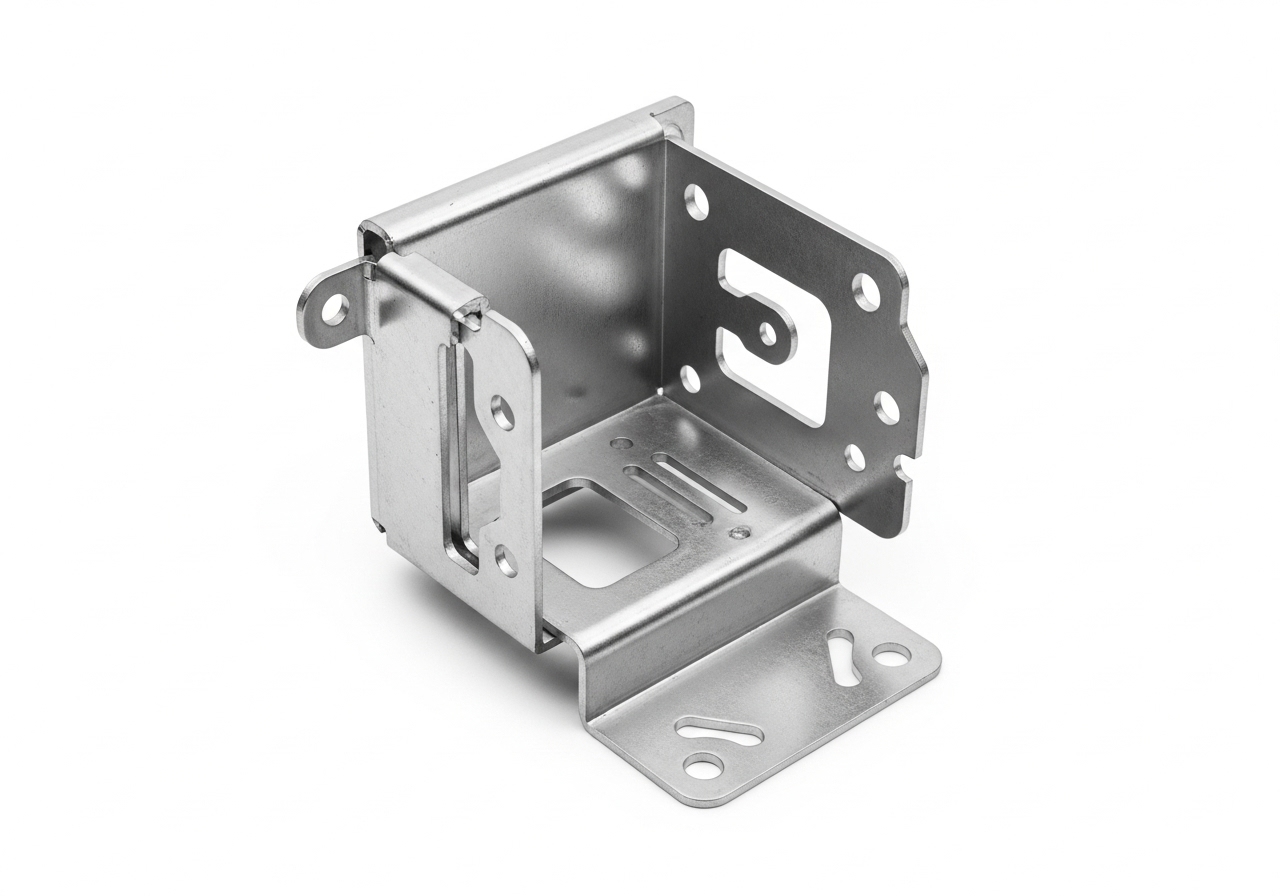

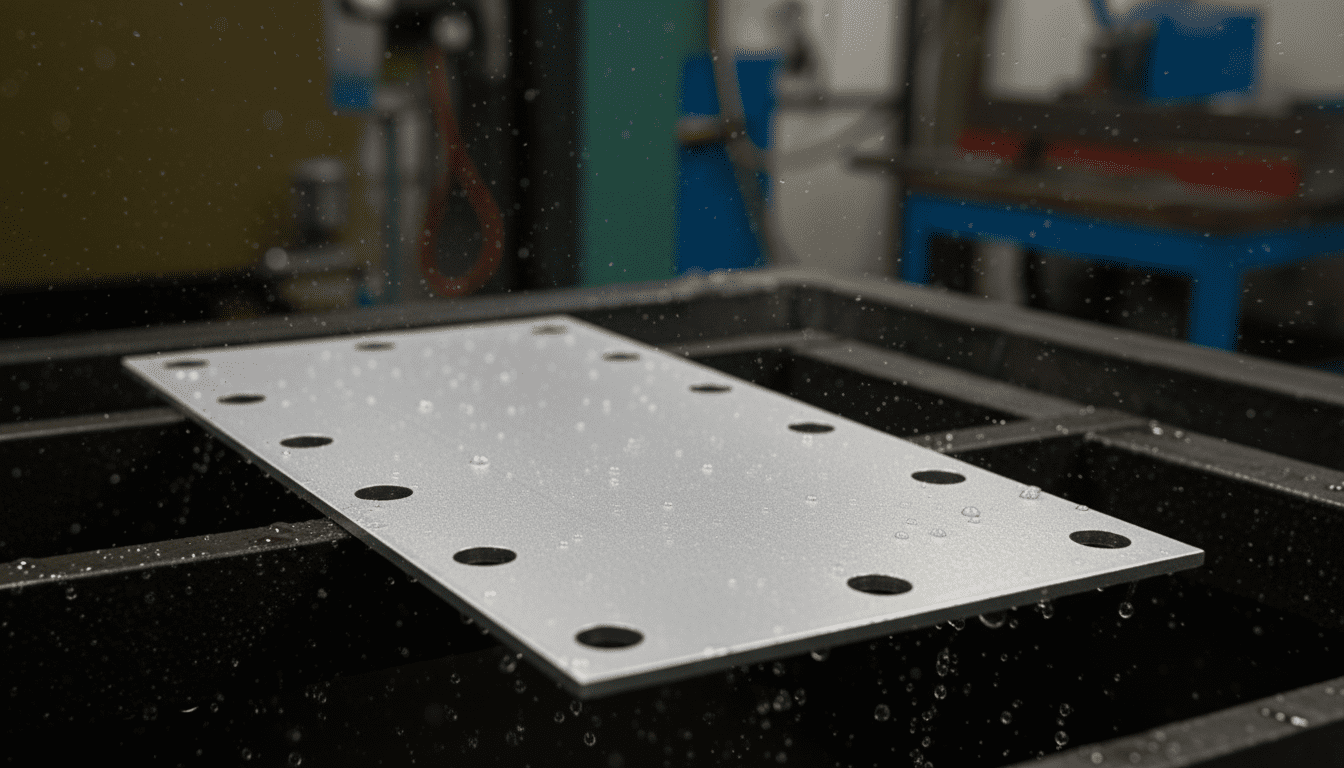

Precision mounting brackets engineered for secure installation and reliable support of heavy equipment and structural components

Precision-engineered electronic control box housings providing optimal protection and accessibility for control systems and electronic components

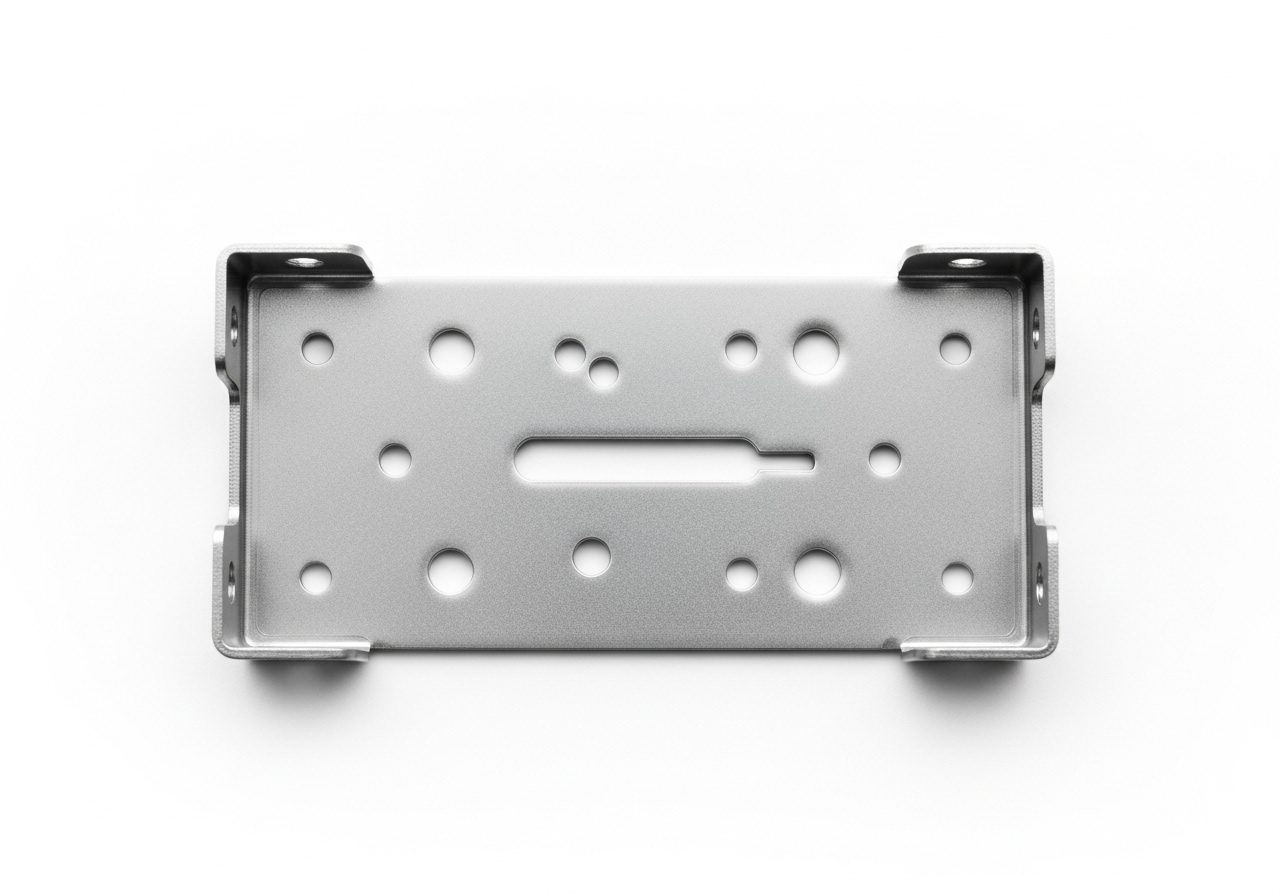

Space-efficient compact device bracket covers designed for secure mounting and protection of small to medium-sized electronic devices

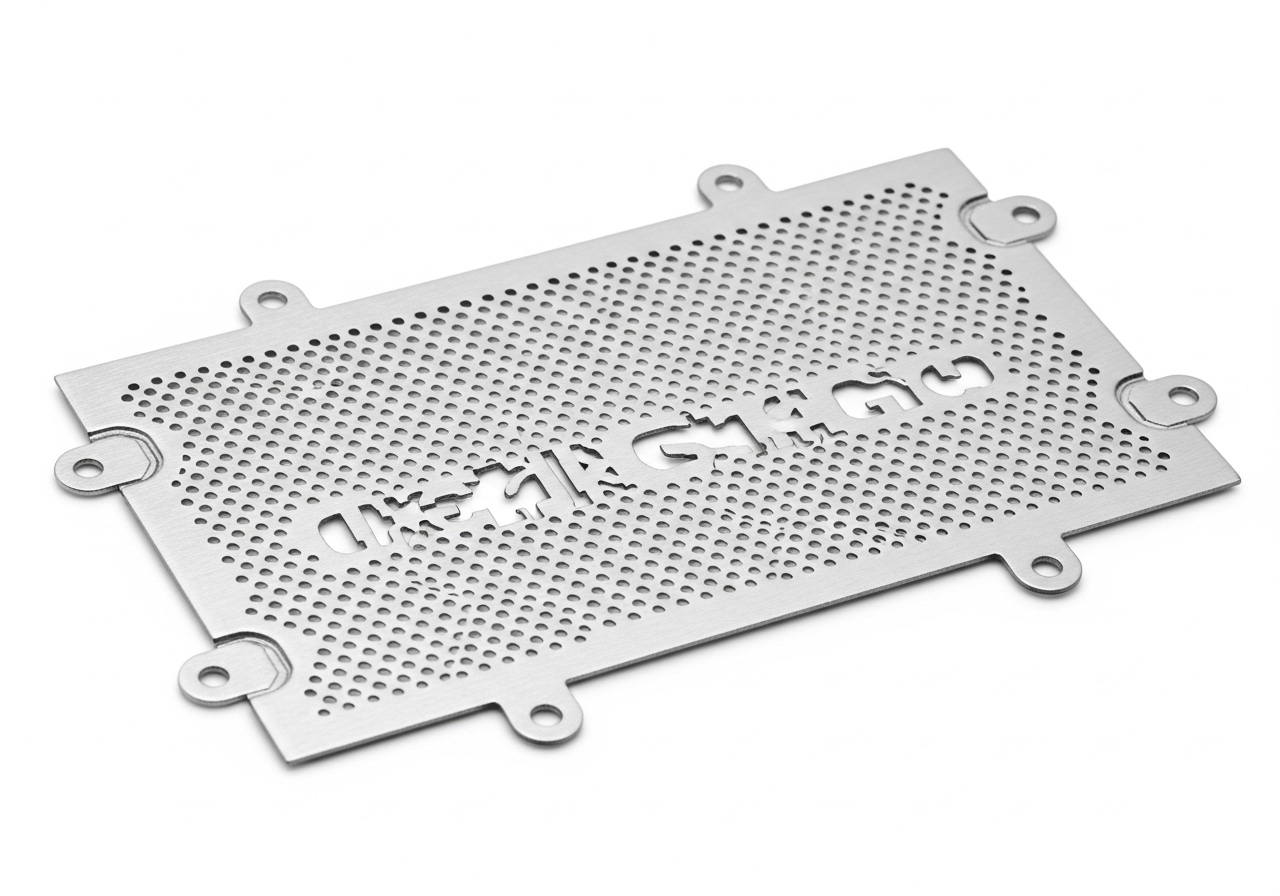

Advanced ventilation enclosures with optimized heat dissipation features for thermal management of high-performance electronic equipment

Precision side mounting panels designed for lateral installation and secure attachment of equipment and components in industrial applications

Specialized instrument shell housings providing precise protection and optimal environmental sealing for sensitive measurement and monitoring equipment

High-quality flat top cover plates engineered for reliable sealing and easy access, ideal for equipment maintenance and component protection

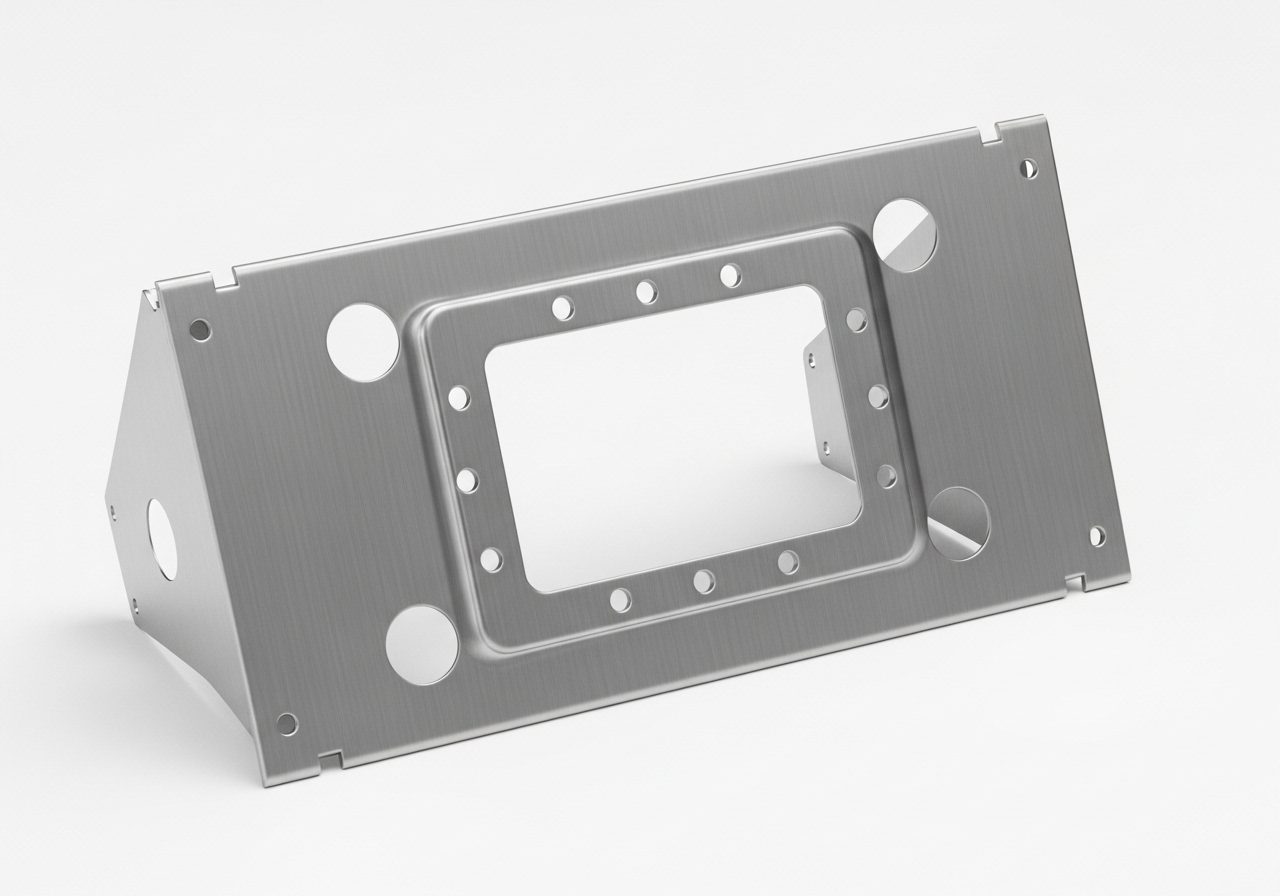

Robust equipment chassis frames providing structural foundation and mounting platform for complex industrial equipment and electronic systems

Our expert engineering team specializes in developing precision sheet metal components tailored to your exact specifications and industrial requirements.

Comprehensive material properties and performance characteristics for precision stamping applications

| Material | Grade/Standard | Tensile Strength (MPa) | Yield Strength (MPa) | Thickness Range (mm) | Applications |

|---|---|---|---|---|---|

| Carbon Steel | AISI 1008-1020 Cold Rolled |

270-450 | 140-380 | 0.3-6.0 | Automotive brackets, appliance components, general hardware |

| Stainless Steel | 304/316L Austenitic |

515-620 | 205-310 | 0.5-3.0 | Food processing, medical devices, marine applications |

| Aluminum Alloy | 5052/6061 Heat Treatable |

190-310 | 145-275 | 0.8-5.0 | Aerospace components, electronics housings, lightweight structures |

| Brass | C260/C360 Free Machining |

300-450 | 125-200 | 0.5-3.0 | Electrical contacts, decorative hardware, precision instruments |

| Copper | C101/C110 Oxygen Free |

220-290 | 70-270 | 0.3-2.5 | Electrical conductors, heat exchangers, plumbing fittings |

| Spring Steel | 65Mn/50CrV4 Hardened & Tempered |

1200-1600 | 900-1400 | 0.2-2.0 | Springs, clips, fasteners, automotive suspension components |

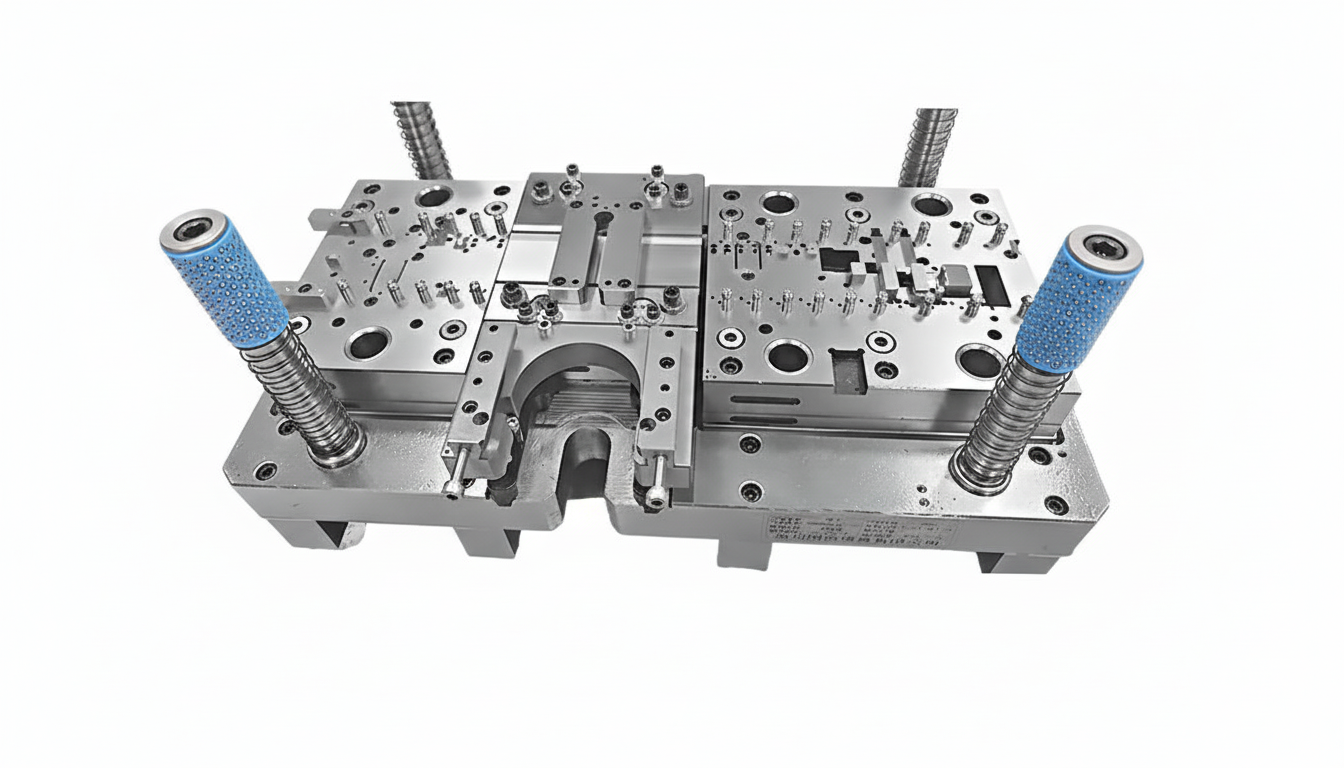

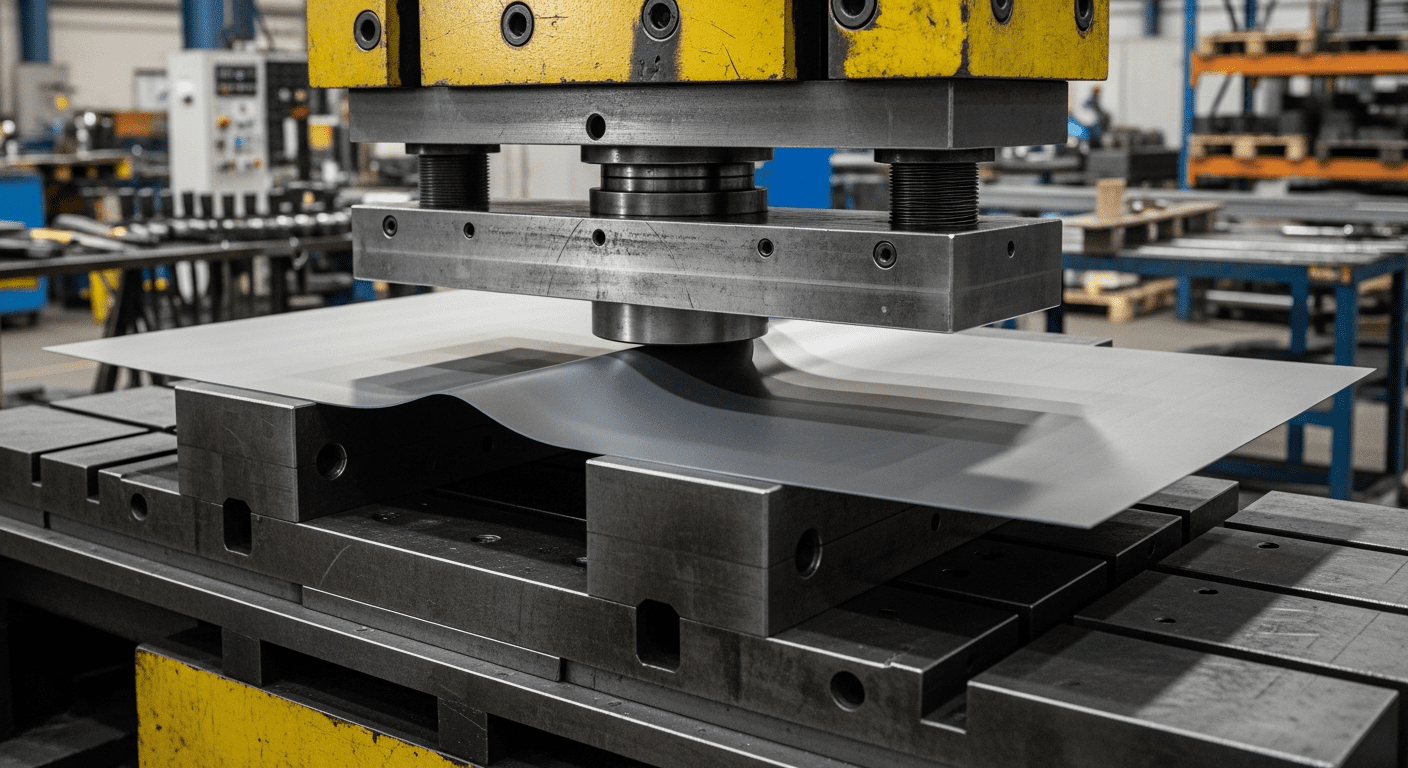

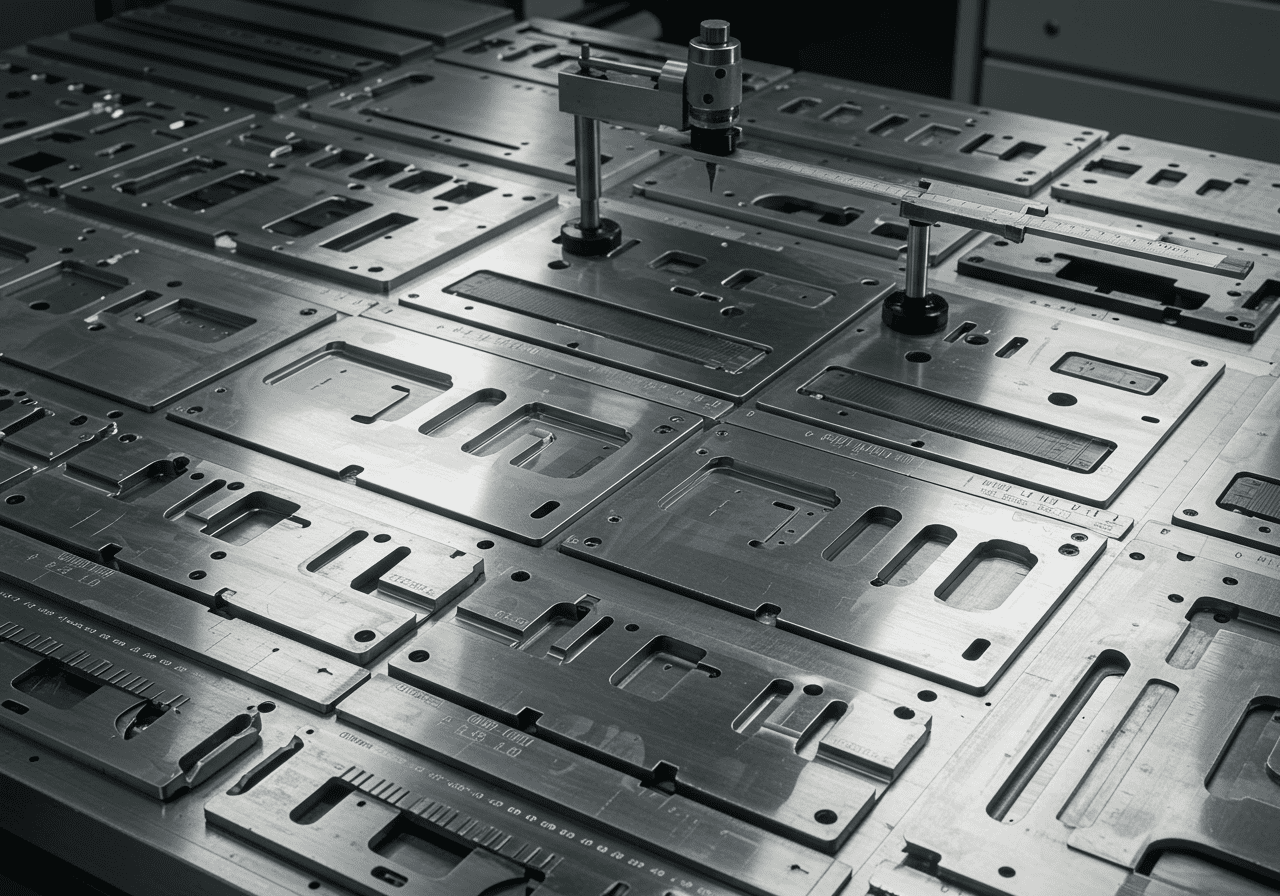

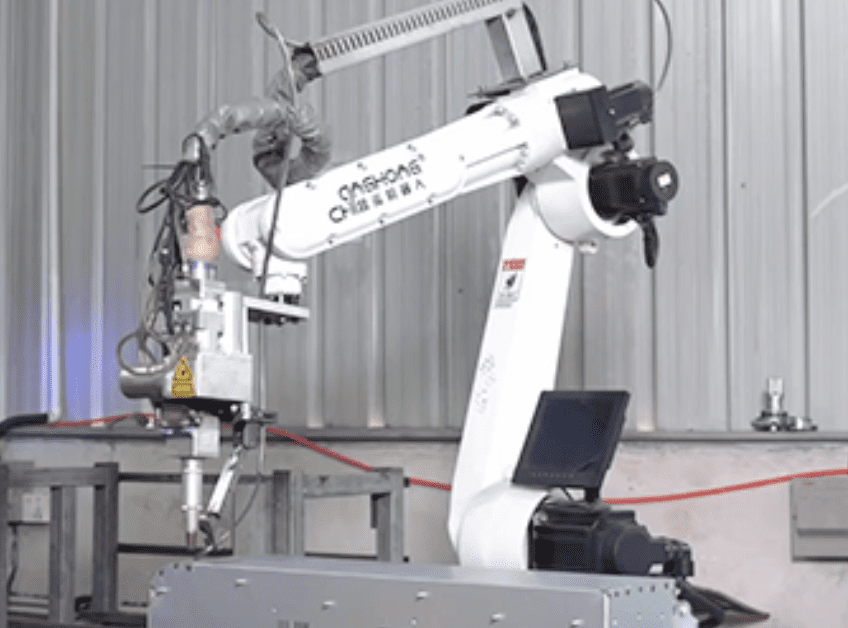

State-of-the-art stamping machinery and tooling solutions with 10 dedicated production lines for precision metal component manufacturing

Multi-stage continuous stamping for efficient mass production with precise sequential operations

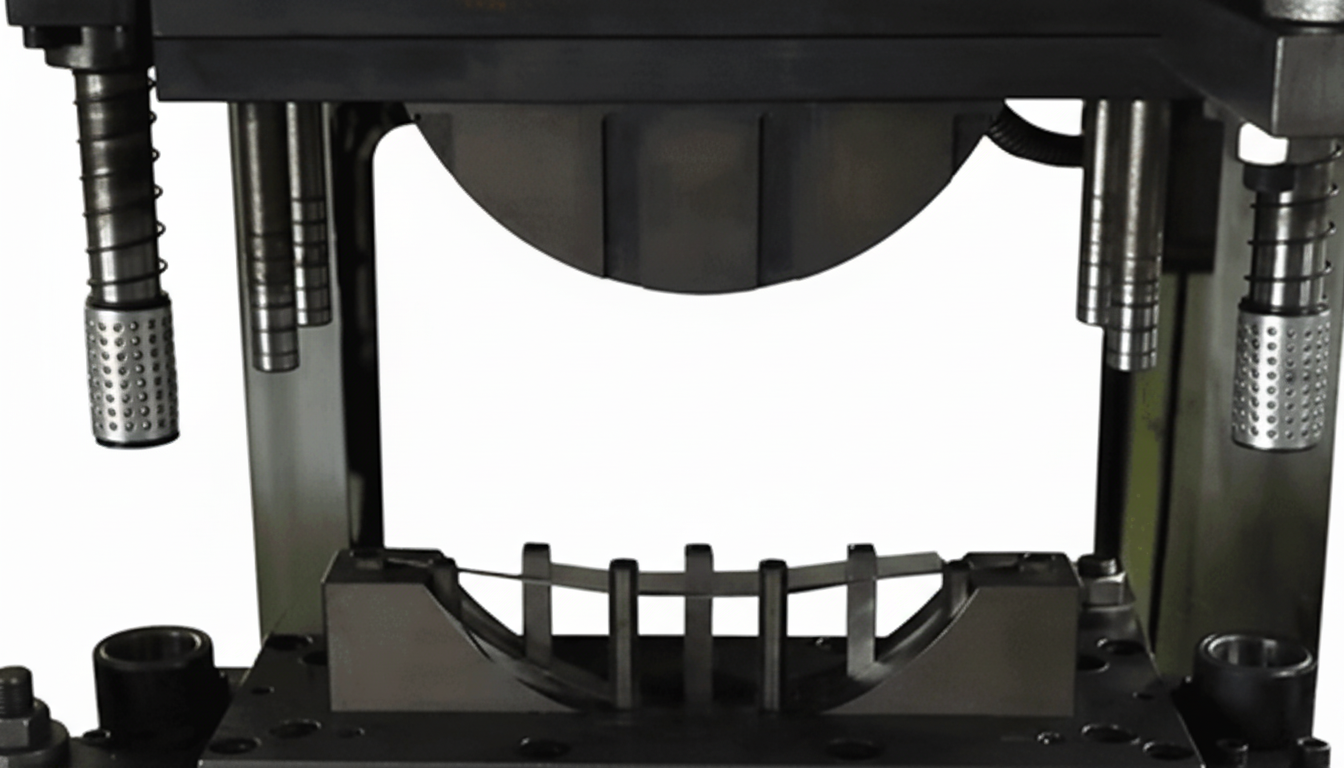

Deep drawing forming process for cylindrical components with superior surface finish

Single operation process for small batch production with maximum precision control

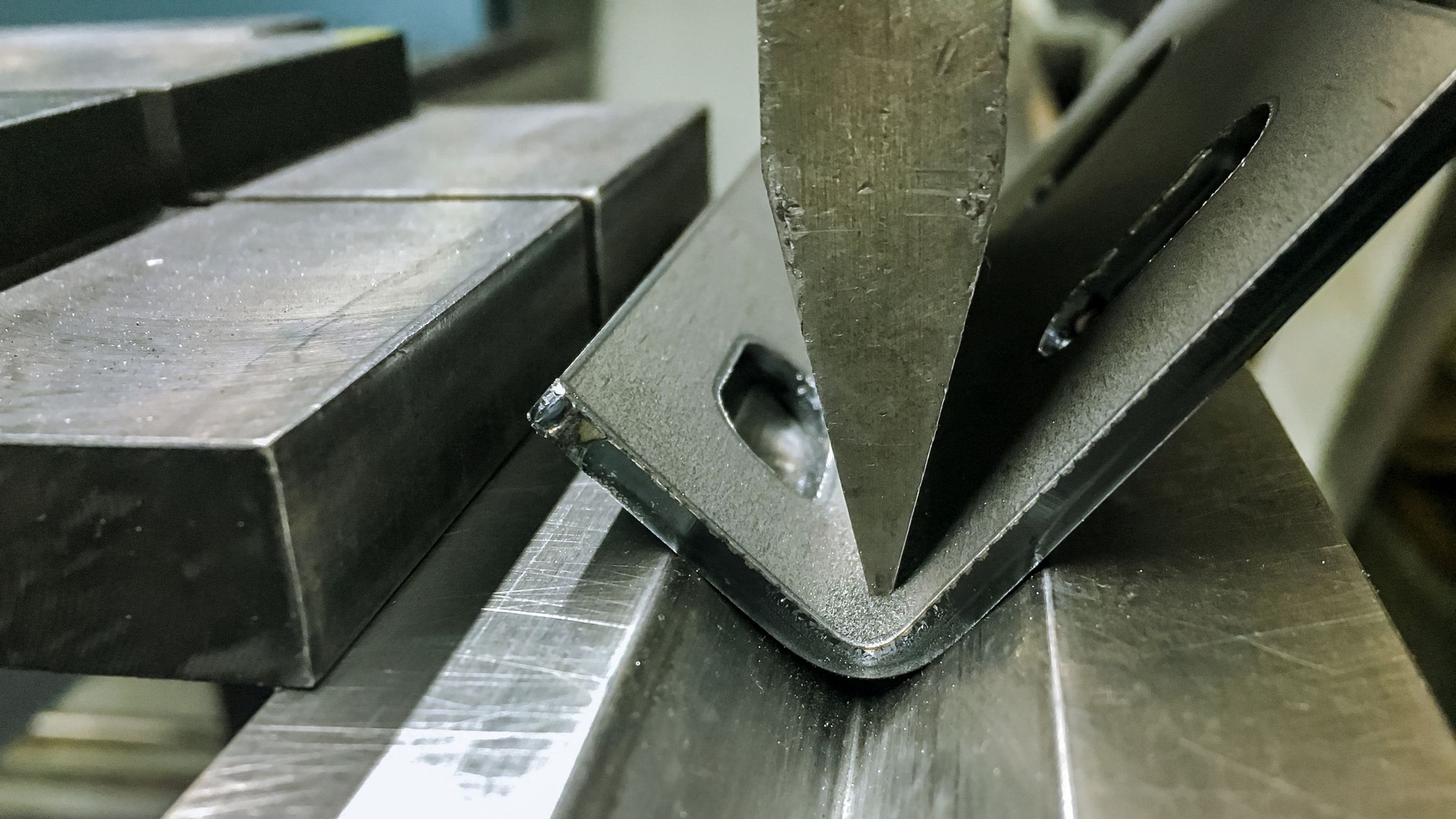

Precision angle forming for bracket components with consistent bend quality

Automated material feeding systems for continuous production flow and optimal efficiency

From concept to delivery - experience our comprehensive manufacturing process with advanced surface treatments

Premium grade materials undergo rigorous inspection and preparation for optimal bracket production quality.

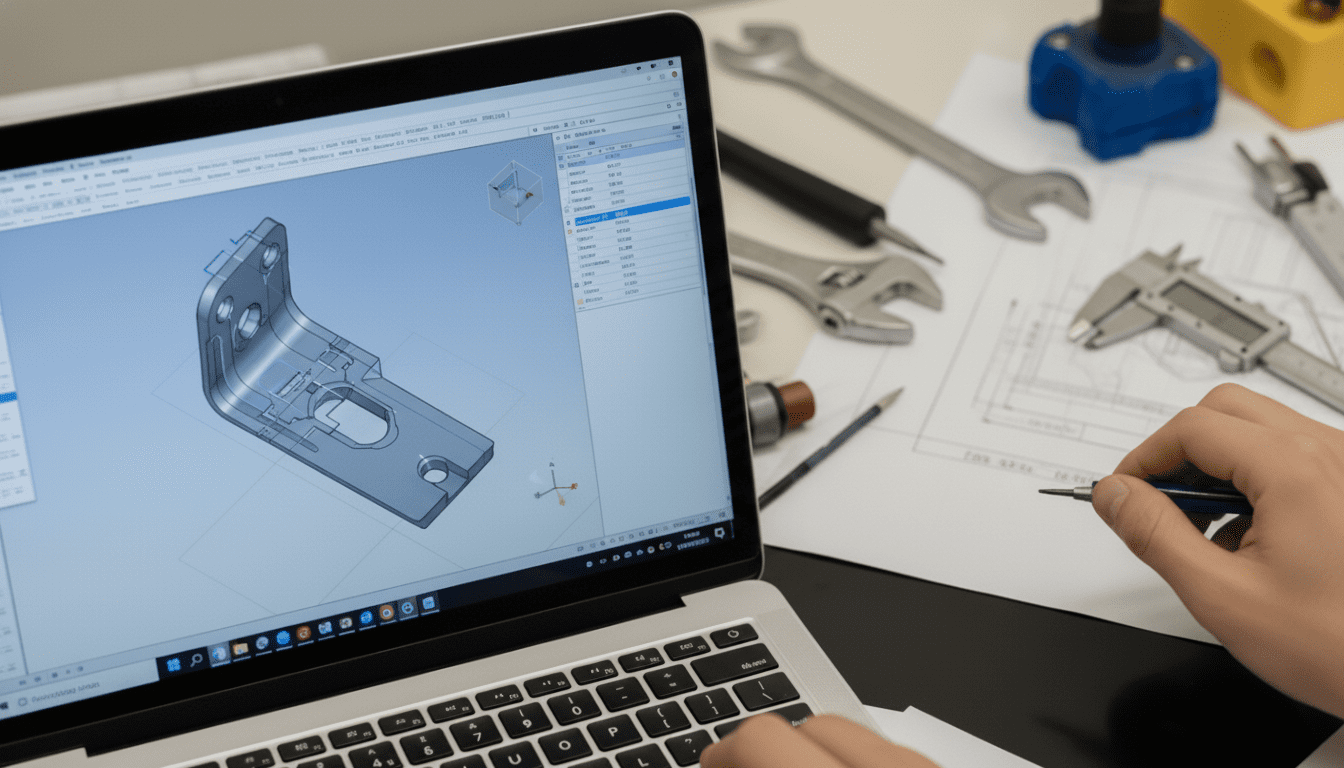

Advanced CAD/CAM systems create precision dies with comprehensive DFM analysis for optimal manufacturing.

10 automated production lines deliver consistent precision with real-time monitoring and quality control systems.

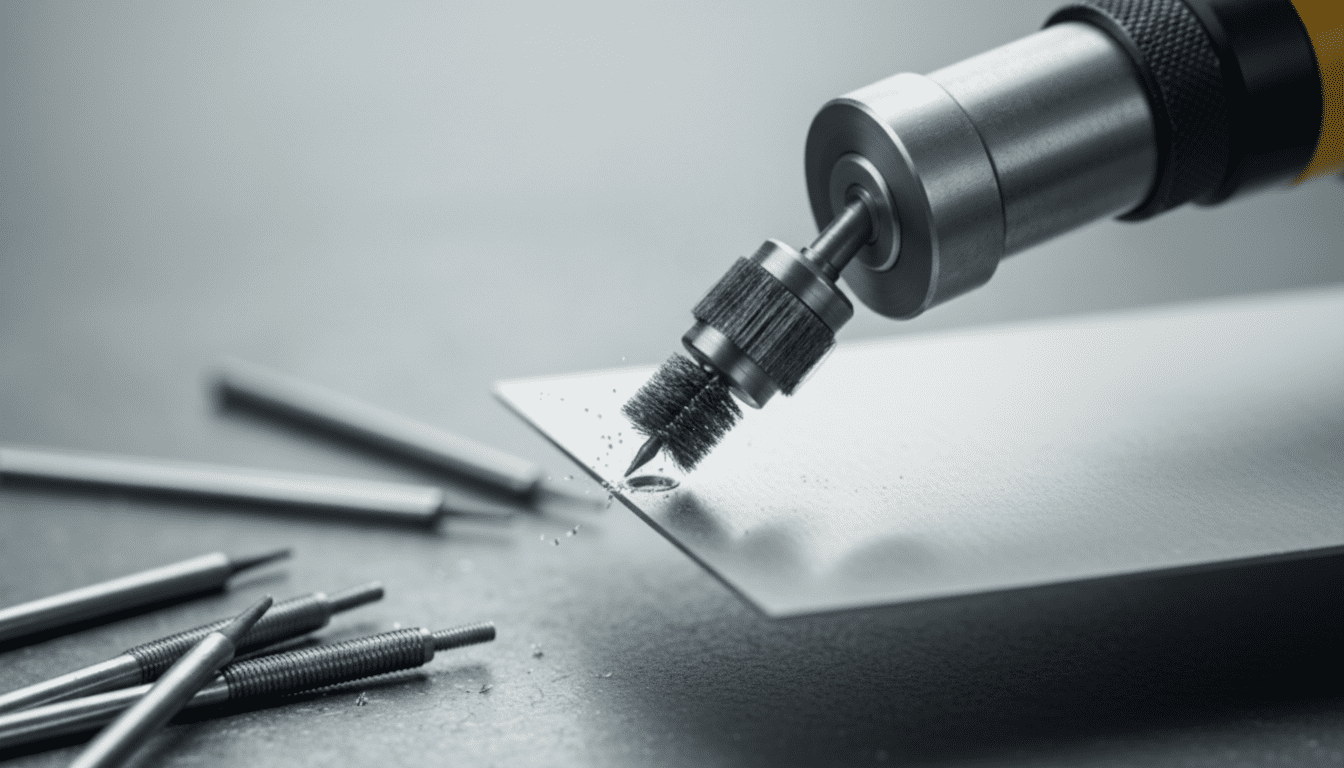

Precision deburring removes sharp edges and imperfections ensuring smooth, safe handling and optimal fit.

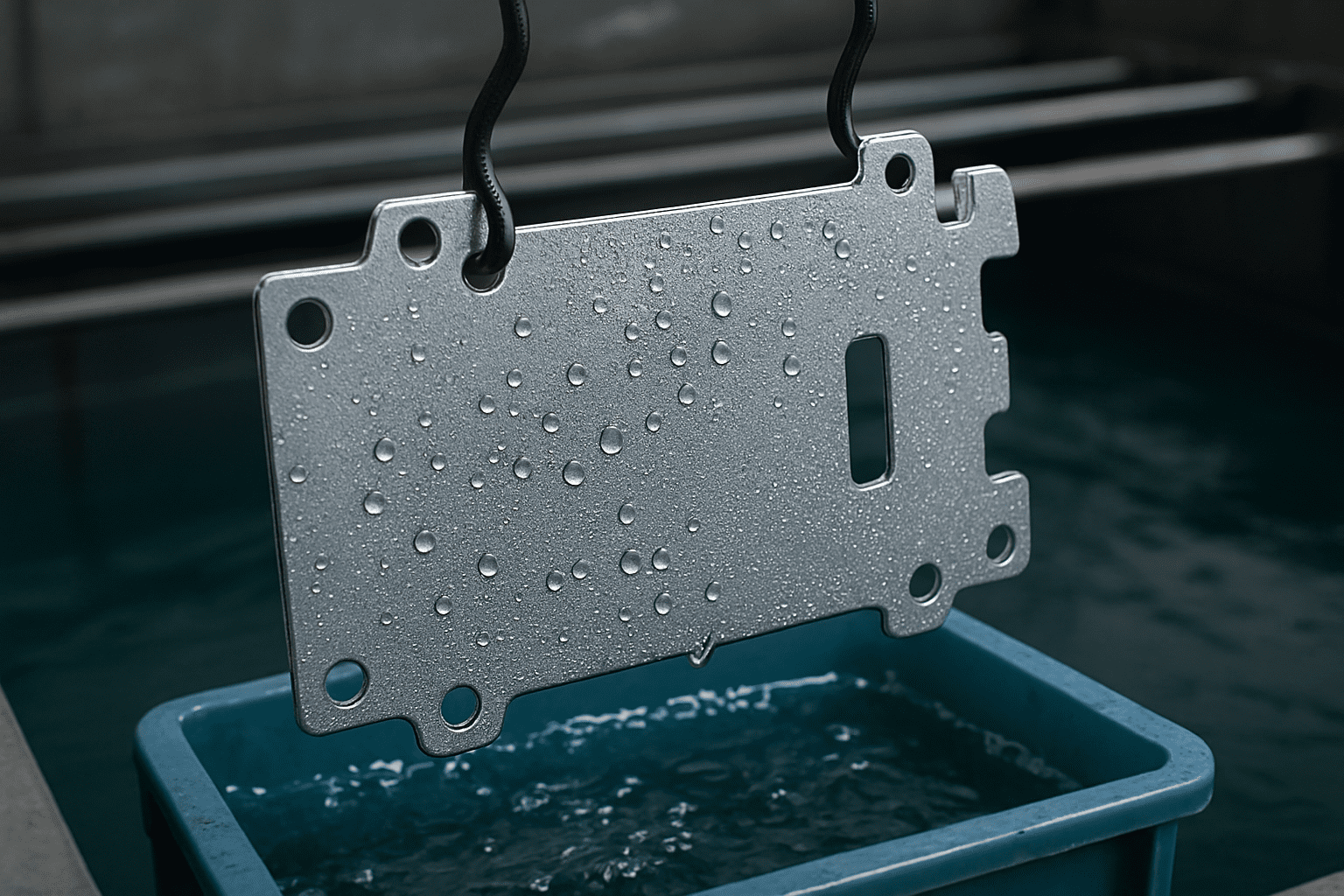

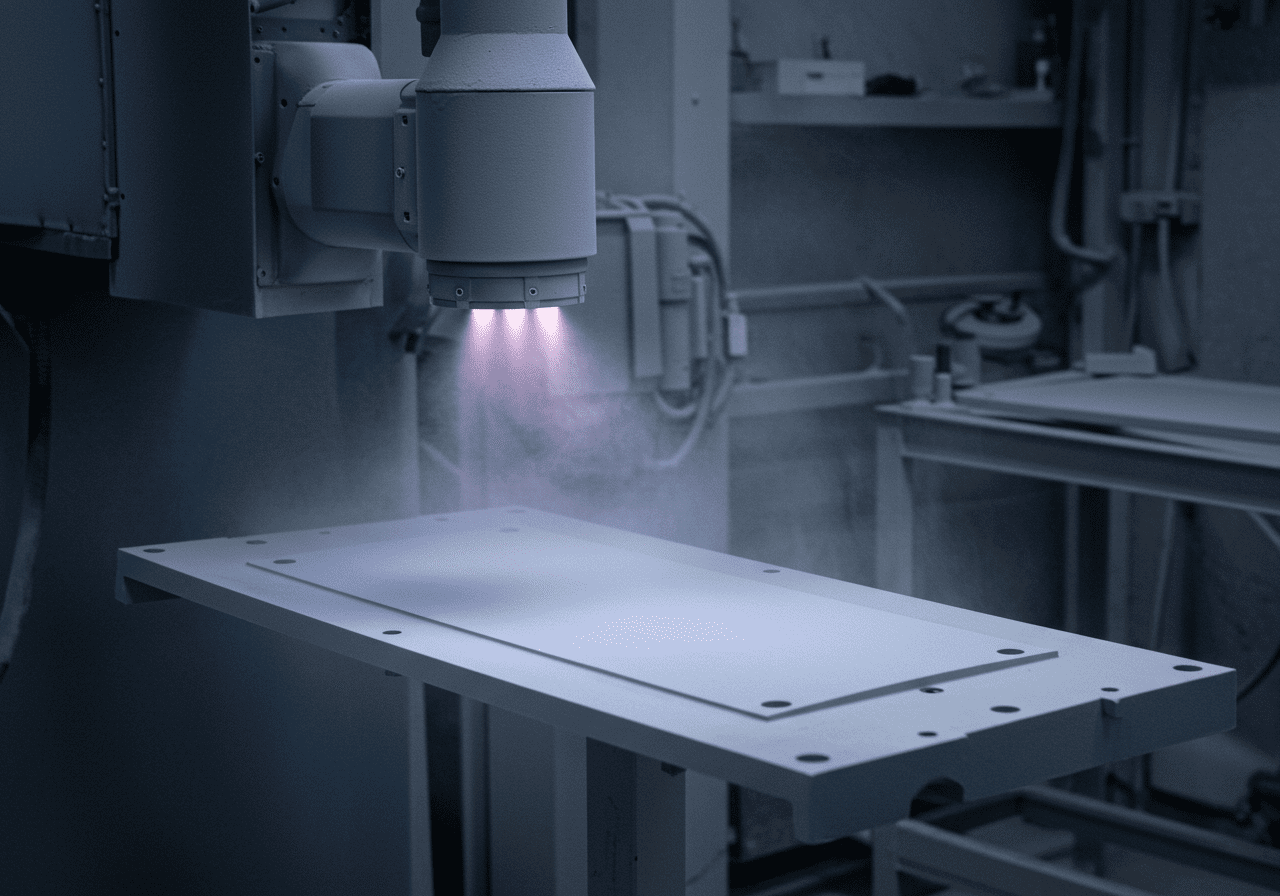

Advanced electroplating processes provide superior corrosion resistance and enhanced durability for demanding applications.

Professional anodizing creates protective oxide layers with excellent wear resistance and aesthetic appeal.

Durable powder coating provides exceptional finish quality with superior color retention and environmental protection.

ISO-certified quality inspection ensures every component meets strict specifications with complete traceability documentation.

Secure industrial packaging with protective materials ensures damage-free delivery and easy handling for global shipments.

Reliable logistics network delivers to North America, Europe, Middle East, and Australia with full tracking and documentation.

From precision electronics to heavy industrial equipment, our custom sheet metal stamping solutions deliver unmatched quality and reliability across diverse manufacturing sectors worldwide.

Precision custom sheet metal stamping for automotive brackets, chassis components, and structural reinforcements. Meeting strict automotive quality standards with exceptional dimensional accuracy.

Ultra-precise custom sheet metal stamping for electronic enclosures, heat sinks, and connector housings. Specialized in micro-stamping and high-frequency shielding applications.

Mission-critical custom sheet metal stamping for aerospace applications requiring extreme precision and reliability. Certified processes for aviation-grade materials and specifications.

Biocompatible custom sheet metal stamping for medical devices and diagnostic equipment. Sterile manufacturing processes meeting FDA and medical industry quality requirements.

Heavy-duty custom sheet metal stamping for power generation equipment, renewable energy systems, and electrical infrastructure. High-voltage rated components with superior conductivity and insulation properties.

Robust custom sheet metal stamping for manufacturing equipment, conveyor systems, and industrial automation. Engineered for continuous operation in demanding production environments.

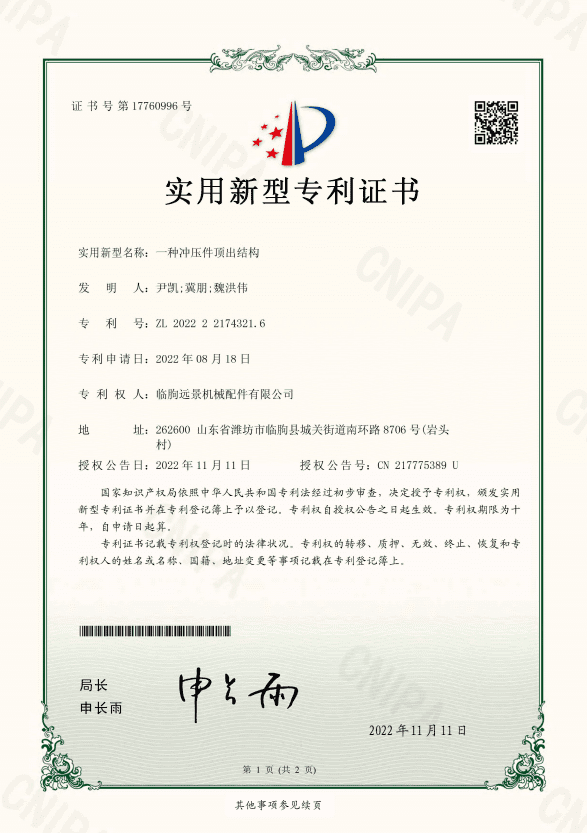

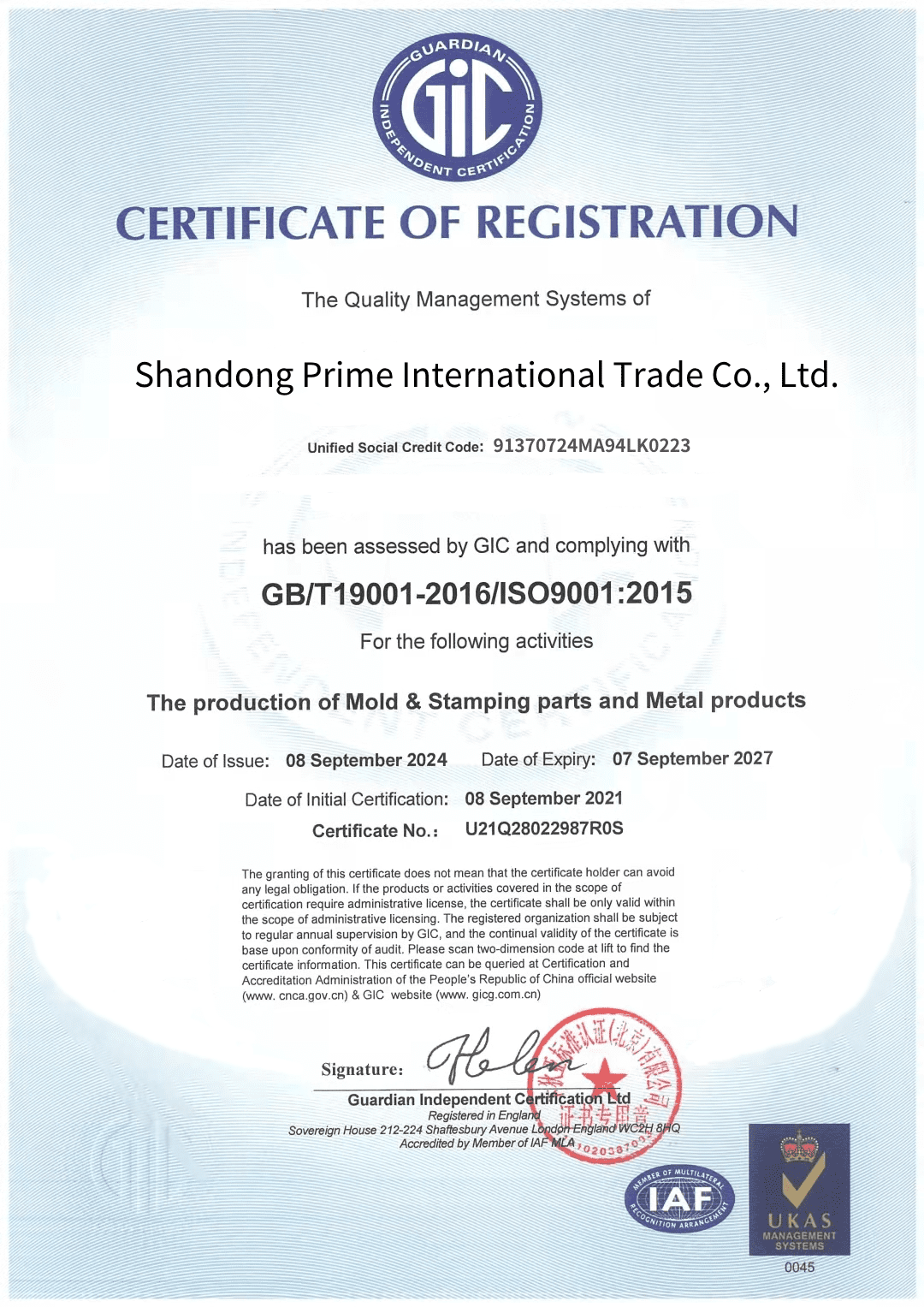

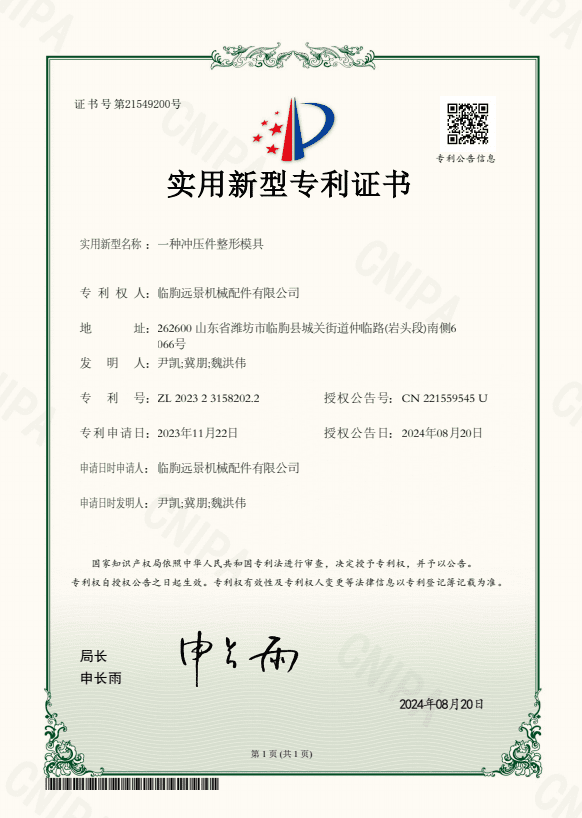

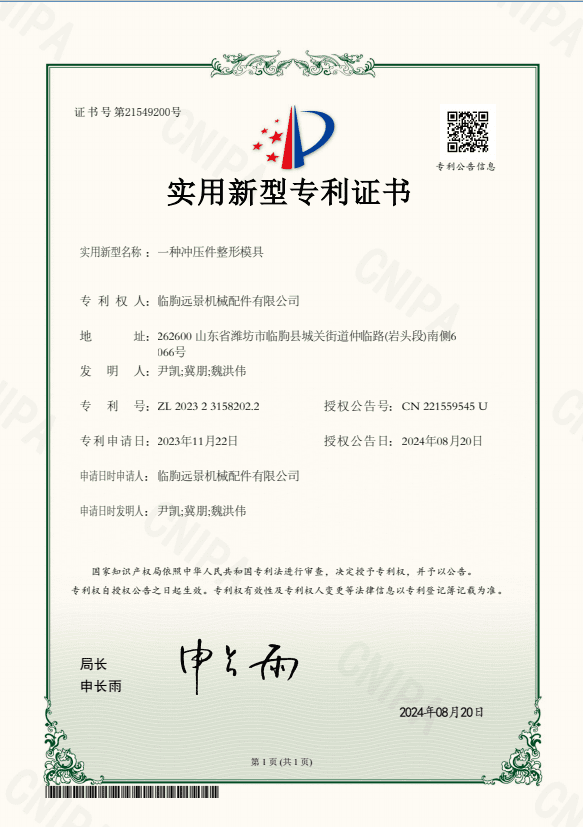

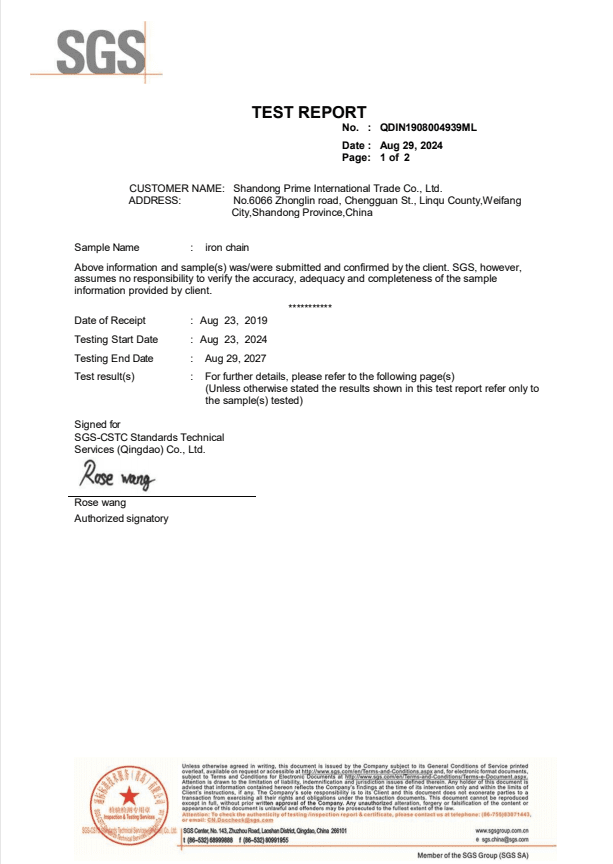

Over 30 years of excellence backed by international certifications and rigorous quality standards. Our commitment to quality ensures every product meets global manufacturing requirements.

International quality management system certification ensuring consistent excellence

Comprehensive quality control processes at every stage of production

Meeting international manufacturing standards for worldwide market compliance

Hear from our satisfied customers across North America, Europe, Middle East, and Australia

"山東プライム社との30年以上の協力関係において、彼らの精密金属スタンピング技術は我々の期待を常に上回っています。ISO認証の品質管理と迅速な納期により、我々の生産計画が円滑に進行しています。"

"Die Präzision und Qualität der Metallstanzteile von Shandong Prime entsprechen den höchsten deutschen Industriestandards. Ihre 10 Produktionslinien gewährleisten eine zuverlässige Lieferkette für unsere anspruchsvollen Automobilprojekte."

"Shandong Prime has been our go-to supplier for custom metal stamping parts for over 8 years. Their engineering team's expertise and flexible customization capabilities have helped us optimize our designs while maintaining cost-effectiveness."

"Shandong Primes metallstansdelar uppfyller våra stränga nordiska kvalitetskrav. Deras ISO-certifiering och pålitliga leveranser har varit avgörande för våra industriella projekt inom förnybar energi."

"Fair dinkum, Shandong Prime's been a ripper partner for our mining equipment components. Their quick turnaround times and spot-on quality control have kept our operations running smooth as silk across the Outback."

"L'excellence technique de Shandong Prime dans l'emboutissage métallique correspond parfaitement aux exigences de l'industrie française. Leur capacité de production de 10 lignes assure une flexibilité remarquable pour nos commandes sur mesure."

"D'Qualität vo de Metallstanzteile vo Shandong Prime entspricht üsne höchste Schwiizer Asprüch. Ihri über 30-jährig Erfahrig und d'ISO-Zertifizirig garantiere üs e zueverlässigi Partnerschaft für üsi Präzisionsinstrument."

Explore our world-class production facility featuring advanced metal stamping technology, rigorous quality control systems, and comprehensive manufacturing capabilities spanning 30+ years of industrial excellence.

Find answers to the most frequently asked questions about our metal stamping services, ordering process, quality standards, and delivery options.

Join hundreds of satisfied clients worldwide. Share your requirements and receive a detailed quote within 24 hours.

Confidential Information: All technical drawings, specifications, and project details are kept strictly confidential and never shared with third parties.

Secure Data Handling: Your contact information and files are stored securely and used only for project communication and quote preparation.

No Spam Guarantee: We respect your inbox. You'll only receive relevant project updates and our occasional industry insights newsletter (opt-out anytime).

ISO Compliance: Our data handling practices meet international ISO standards, ensuring your information is managed with the highest level of security.

"30+ years of trusted partnerships built on confidentiality and integrity"